Design and Development

- Converting an idea or concept into Engineering drawings

- Transforming drawings and simulations

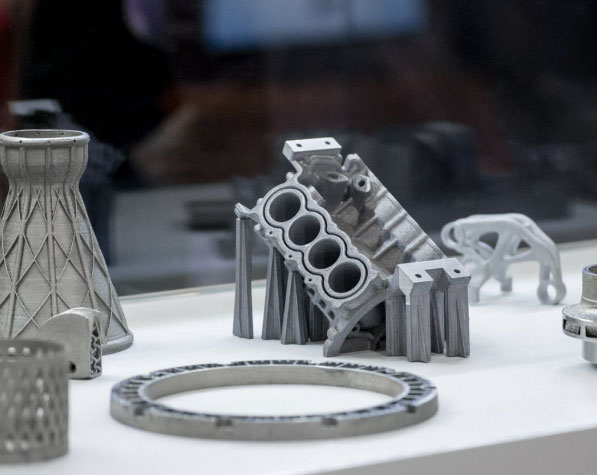

Prototyping

- Conversion of drawings and simulations into a functioning prototype

- Crystallizing the different technical specifications for the prototype from the concept stage

- Identification of the ideal components to meet the specifications

- Fabrication of the components through their different iterative stages

- Technical Negotiation with vendors to identify the best fit for the components required

- Final assembly of the Prototype

Testing and Validation

- Rigorous testing to validate the functioning of the prototype

- Preparation of custom equipment to aid us in product testing

Manufacturing

- Design transfer to transform a prototype into a packaged product for the market

- Quality Management System development to maintain Quality of the manufactured product

- Preparation of SOPs, Work Instruction, Batch Manufacturing Records to maintain manufacturing quality, reproducibility and traceability

- Packing Design and Fabrication

- Customized Process Equipment

- Contract Manufacturing of sterile and unsterile products

Regulatory Support

- We are also experienced in Document Management to prepare regulatory documents to meet the different licensing requirements

- We have expertise in the end to end regulatory filings across the life cycle of a new product – from concept, risk management to post market surveillance